MB 600-080

Anchorage Principle

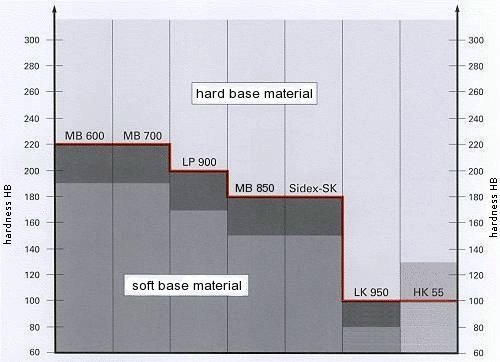

The required bore roughness is directly related to the hardness and the mechanical characteristics of the base material. Depending on the combination of sealing plug and base material, anchorage takes place either by the groove profile of the expander sleeve biting into the base material or on anchorage to the surface roughness of the bore.

Note:

When selecting a KOENIG Expander® the bore roughness must always be adjusted according to the hardness of the base material.

Anchorage principle related to the base material

![]()

Hard base material: to achieve the allowable working pressure, anchorage to the bore roughness or the base material is required. Roughness Rz = 10 to 30 µm. ![]()

Soft base material: anchorage to the bore of the base material occurs automatically due to the serrations on the sleeve of the KOENIG Expander®. ![]()

Soft base material: anchorage is not possible with the HK series. Such combinations are not allowed for high pressure applications. ![]()

Transition zone: to achieve the allowable working pressure, anchorage to the bore roughness of the base material is required. Roughness Rz = 10 to 30 µm.

Anchorage due to plug sleeve serrations

KOENIG Expander® series MB 850 in aluminium alloy HB = 90

Anchorage due to plug sleeve serrations

KOENIG Expander® series SK in aluminium alloy HB = 90

Anchorage due to bore roughness

KOENIG Expander® series HK 55 gray cast iron HB = 160

Sufficient anchorage due to plug sleeve serrations

KOENIG Expander® series LK 950 in aluminium alloy HB = 90

Anchorage due to plug sleeve serrations

KOENIG Expander® series LP 900 in aluminium alloy HB = 90